Upon looking online, there are many posts about checking the actual travel as opposed to a calculation to verify measurements. The most basic was to place a machinist ruler and physically check the travel. Now, this works for about one inch, but not over longer travel.

The next approach is to test using a dial indicator to produce a more accurate measurement. I would either mount the indicator to the spindle and have the table travel a specific distance. Near the end of travel there would be a solid surface, usually a gauge block, to check how much more it travels into the surface. In other words, if I made it travel 6 inches and I know if passes that mark by roughly half an inch, then I could place the dial and get the exact reading. That number would then be input to Mach3. It hasn’t worked too well with a 1” indicator, so I purchased a 2” version recently.

Now, if you don’t want to check measurements that way, you can calculate the appropriate steps per revolution of the ball screw. Since I am using 12mm diameter screws with a 2.5mm pitch (distance from one thread to the other), I must account for this variation. From what I’ve read, each stepper produces 200 steps per revolution. I’m not sure if that’s clear across the board, maybe someone could clarify that. My Mach3 setup is in Imperial (in) and the screw needs to be converted. So...

25.4mm/inch / 2.5mm = 10.16 inch

This number is then multiplied by the steps per rev (200):

10.16 x 200 = 2,032

And since there are apparently four poles that allow rotation of the motor, you multiply by four.

4 x 2,032 = 8,128

This number is then entered in to Mach3 per axis and should provide proper calibration. I’ll try this and verify with the dial indicator and hopefully all will be accurate. Please comment if you know any other way or if there are any corrections to what I am doing.

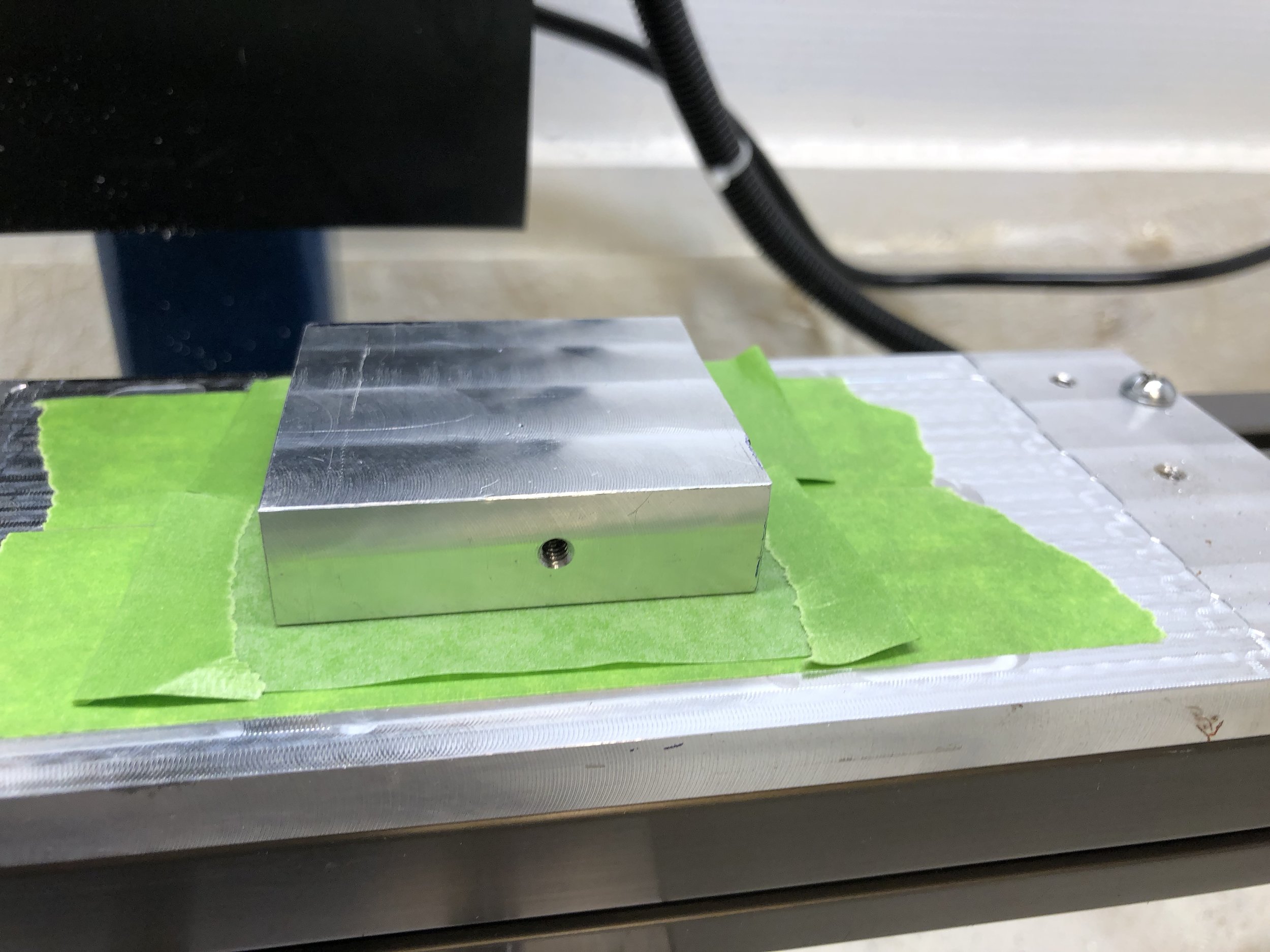

The next task for me was to tramm the mill, or basically square it up so I have a flat working surface.